In industries such as pharmaceuticals, food additives, and high-end chemicals, manufacturers often face a critical challenge: how to uniformly disperse trace-level key ingredients, such as vitamins, flavorings, or catalysts, into a large volume of base material. When micro-ingredients are mixed improperly, product batches may result in inconsistent quality or, in severe cases, pose safety risks. Therefore, ensuring mixing homogeneity becomes especially crucial when dealing with extremely demanding ratios such as 1:10,000, where precision directly affects product performance and quality.

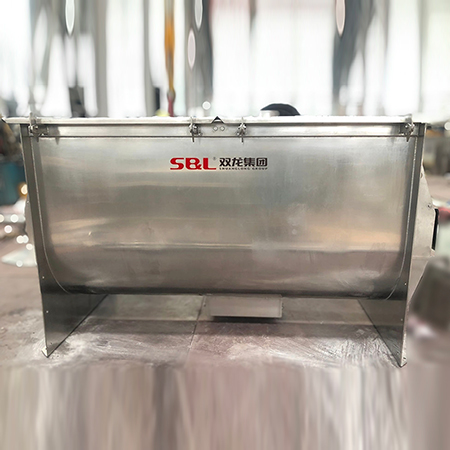

Ribbon mixer provides an effective solution through its unique structural design. Through the coordinated action of inner and outer helical ribbons, the mixer creates strong convective and shear mixing within the vessel.

- The outer ribbon drives material from both sides of the U-shaped vessel to gather toward the center.

- The inner ribbon simultaneously moves to push back the material accumulated at the center toward both sides.

This “push–pull” counterflow pattern generates powerful convective and shear forces inside the chamber, enabling trace-level ingredients to rapidly and evenly disperse into the bulk material—reliably achieving mixing ratios as precise as 1:10,000. Shuanglong Group optimizes this performance through meticulous and precise engineering of ribbon angles, pitch, and the clearance between ribbon and vessel wall. These optimizations ensure smooth material flow paths and consistent distribution, effectively preventing any uneven distribution during mixing.

With Shuanglong’s ribbon mixer, clients can achieve reliable, uniform mixing at ratios up to 1:10,000, with the Coefficient of Variation (CV) consistently controlled at ≤7%. This high level of homogeneity provides a solution for product consistency, reduces risks associated with uneven mixing, and lowers operational costs—helping manufacturers strengthen their competitive edge in demanding, high-precision industries.