Our client is a well-known food manufacturing company in Jordan, widely recognized across the regional market. Their product range includes nut-based snacks, fried snacks, chocolates and confectionery, and breakfast cereals.

When faced with the challenge of recipes requiring large amounts of liquid addition, the plough shear mixer is undeniably the ideal choice.

Our cooperation with this client began in 2022. Although the payment process initially encountered some challenges, our teams worked closely together to resolve every issue. Ultimately, the mixer was successfully installed and commissioned.

Once operating, the mixer significantly enhanced the client’s production efficiency. This success strengthened mutual trust between us, leading to a second collaboration in 2024—this time involving a more technically complex mixing project.

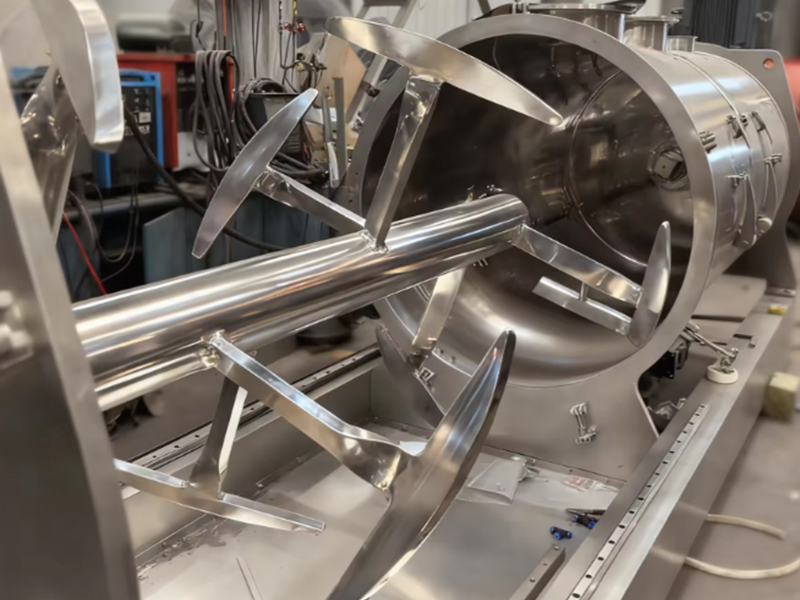

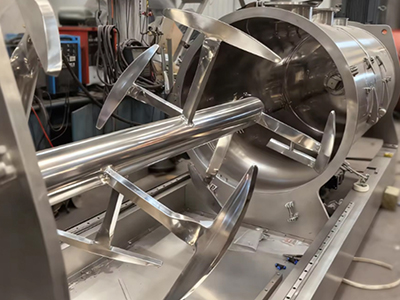

The new project introduced a next-generation electric pull-out mixer with a capacity of 2–3 m³.

Its core advantage lies in its easy daily deep-cleaning capability. After each production cycle, the main shaft can be fully withdrawn for complete cleaning, meeting the strict hygiene requirements of the food industry.

Thanks to Shuanglong’s mature manufacturing expertise, we successfully incorporated this advanced feature while maintaining strict cost control, delivering a highly cost-effective upgrade for the client. Compared with conventional mixers, the non-suspended main shaft design requires higher standards for mixing stability and vibration reduction, and these technical challenges have become the key focus of ongoing optimization for our engineering team.